Raddecom Solutions has over 44 years experience in the Nuclear Sector and are providing novel designs for complex decommissioning problems with cost effective, robust, flexible, sustainable products.

Since 2015 we have been developing a range of precast concrete containers for the interim storage, transport and final disposal of radioactive wastes. In addition we have developed a number of other related products.

Whether you are considering using one of our existing concrete container designs or need a bespoke solution then we can support delivery of a product that will meet your needs.

Take a look at some of the containers that make up our Con-tain Range & a number of our other products!

Decommissioning Innovation for the Nuclear Sector

Since 2015 we have been developing a range of precast concrete containers for the interim storage, transport and final disposal of radioactive wastes. To date we have over 50 registered designs of waste container accepted by the UK Intellectual Property Office (IPO), from simple concrete containers to containers designed for remote handling. A number of these designs have been selected by waste consigners and production units manufactured for use in the field.

Whether you want to use one of our existing concrete container designs or need a bespoke solution then we can deliver a product that will meet your needs.

Our waste container range is branded as:

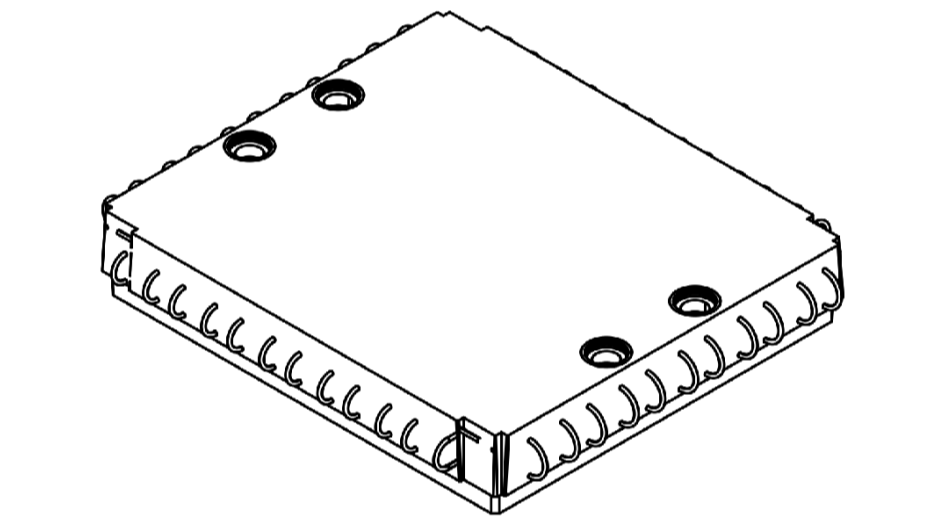

Some examples of our "Con-tain range" of concrete nuclear waste containers are provided below. All containers within the Con-tain range are Registered Designs with the UK Intellectual Property Office.

Decommissioning Concrete Container (DCC) designs are registered designs with the UK Intellectual Property Office.

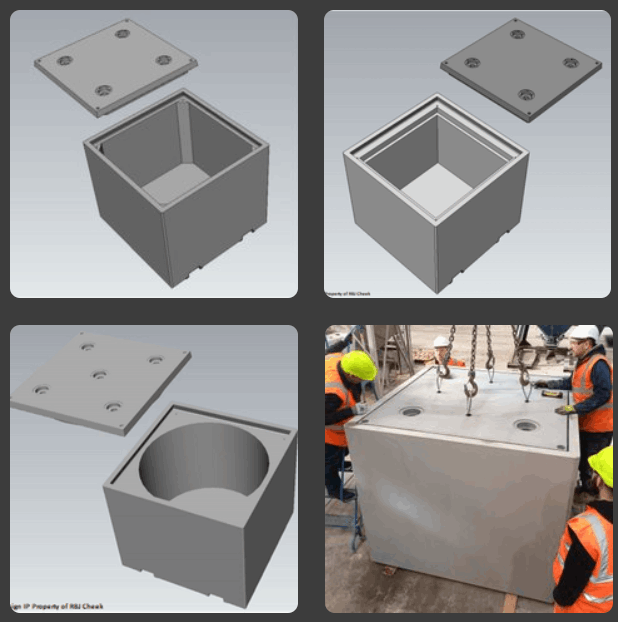

The simplest Decommissioning Concrete Container (DCC) set are Type IP-2 Nuclear Waste Containers designated for use on the waste consigners site for interim storage, transport to and final disposal in an appropriate disposal facility. The simple DCC's are available in three forms, a thin walled and a thick walled version plus a wet waste version. These containers can be manufactured using a normal density, a high density, or a maximum density fibre reinforced concrete mix. In addition, the thick walled and wet waste DCC can be manufactured using steel reinforcing. The two solid waste versions of the simple DCC set have identical external features and dimensions, only the internal cavity is different. The wet waste version has identical external features and dimensions as that of the Solid waste DCC's but does have a a cylindrical cavity and an additional port for the lost paddle mixer. This allows common handling plant and equipment. All concrete containers are leak and pressure tested and are fitted with radiation resistant seals. The simple DCC set can be scaled in overall size to suit customer requirements.

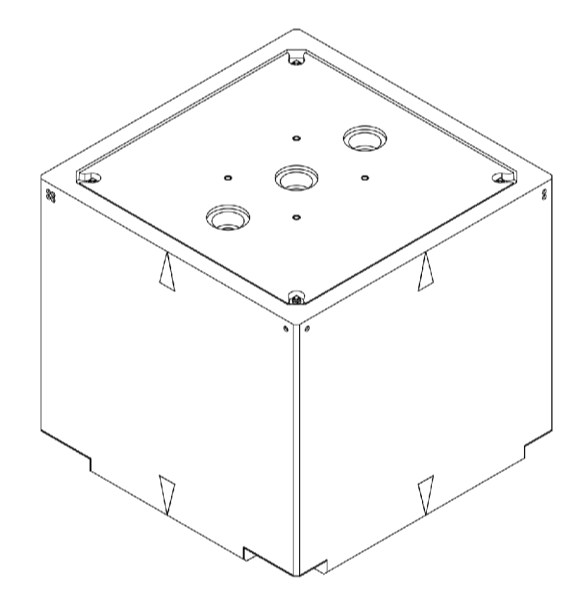

The bottom lift Decommissioning Concrete Container (DCC) designs are designated as a Type IP-2 Nuclear Waste Container for use on the waste consigners site for interim storage, transport to and final disposal in an appropriate disposal facility. These containers can be manufactured using steel reinforcing, metallic or non-metallic fibres in a normal density, a high density, or a maximum density concrete mix. The bottom lifting features negate the need for expensive twistlock pockets by instead using low cost lifting features that best utilise the properties of the concrete. The designs for the bottom lift DCC's can be manufactured to the customers requirements. The designs of the bottom lift decommissioning concrete containers are scalable and can be manufactured to accommodate solid or wet wastes. All concrete containers are leak and pressure tested and are fitted with radiation resistant seals.

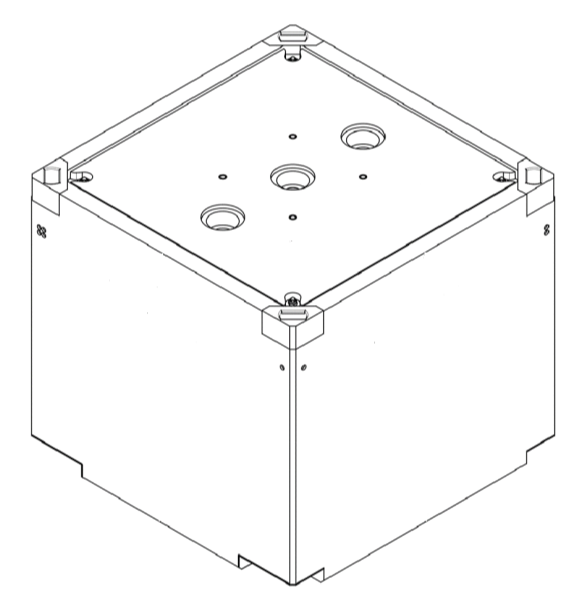

The top lift Decommissioning Concrete Container (DCC) designs are designated as a Type IP-2 Nuclear Waste Container for use on the waste consigners site for interim storage, transport to and final disposal in an appropriate disposal facility. These containers can be manufactured using steel reinforcing, metallic or non-metallic fibres in a normal density, a high density, or a maximum density concrete mix. The lifting features (usually twistlock pockets) can be manufactured to customers requirements. The designs for the top lift decommissioning concrete container are scalable and can be manufactured to accommodate solid or wet wastes. All concrete containers are leak and pressure tested and are fitted with radiation resistant seals.

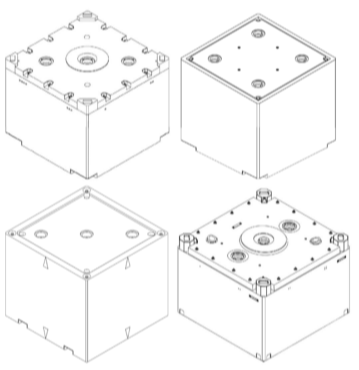

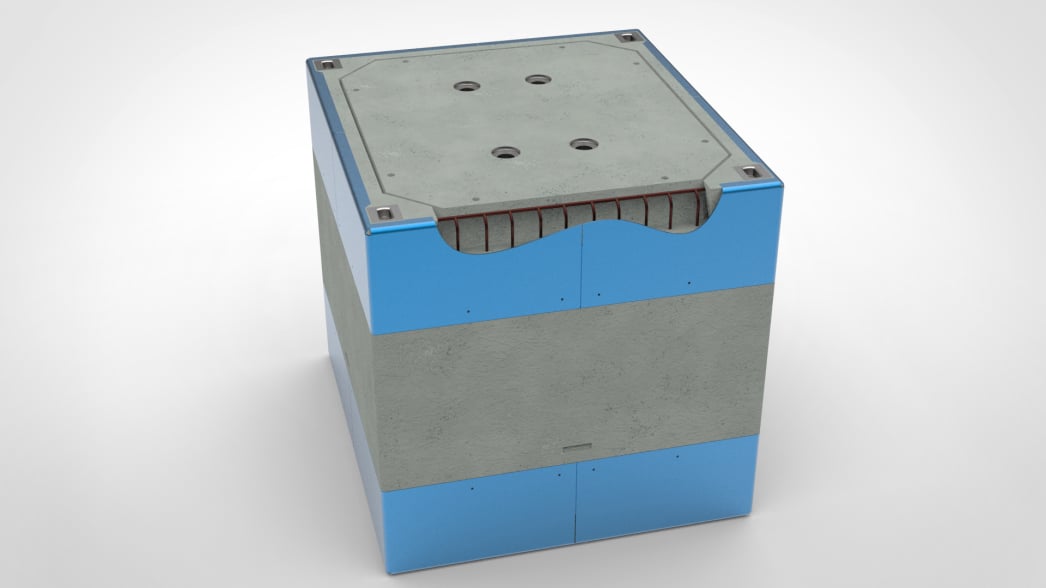

The remotely handled Decommissioning Concrete Container (DCC) designs are designated as a Type IP-2 Nuclear Waste Container for use on the waste consigners site for interim storage, transport to and final disposal in an appropriate disposal facility. These containers can be manufactured using steel reinforcing, metallic or non-metallic fibres in a normal density, a high density, or a maximum density concrete mix. The containers within this range have waste loading and lid handling and fixing features that can be operated remotely negating the need for operators to be in close proximity. The designs of the remotely handled decommissioning concrete containers are scalable and can be manufactured to accommodate solid or wet wastes. This particular illustration has a central large lid lifting feature which utilises the same grab unit that which loads waste drums into the DCC with four drums accommodated within each unit. All concrete containers are leak and pressure tested and are fitted with radiation resistant seals.

The different variants enable waste type, volume and shielding to be optimised (in conjunction with variable concrete mix densities) for each customer whilst maintaining the customers preferred external dimensions and features to ensure common handling and transport requirements are met. If a potential waste consignor requires different internal or external features then this can be accommodated.

Typical options that can be incorporated within the generic designs are bolted or "grout fixed" precast lids, underside or topside lifting features, additional lid ports/inspection ports, additional operational hold down bolts, external steel liners/wraps, internal steel liners, enclosures, lost paddle for wet waste mixing, skeletal bump cage, alternative lifting features, application of de-contaminable and protective coatings, remote handling features, internal furniture etc.

Utilising High Performance Concrete Universal Shielding Blocks (USB's)

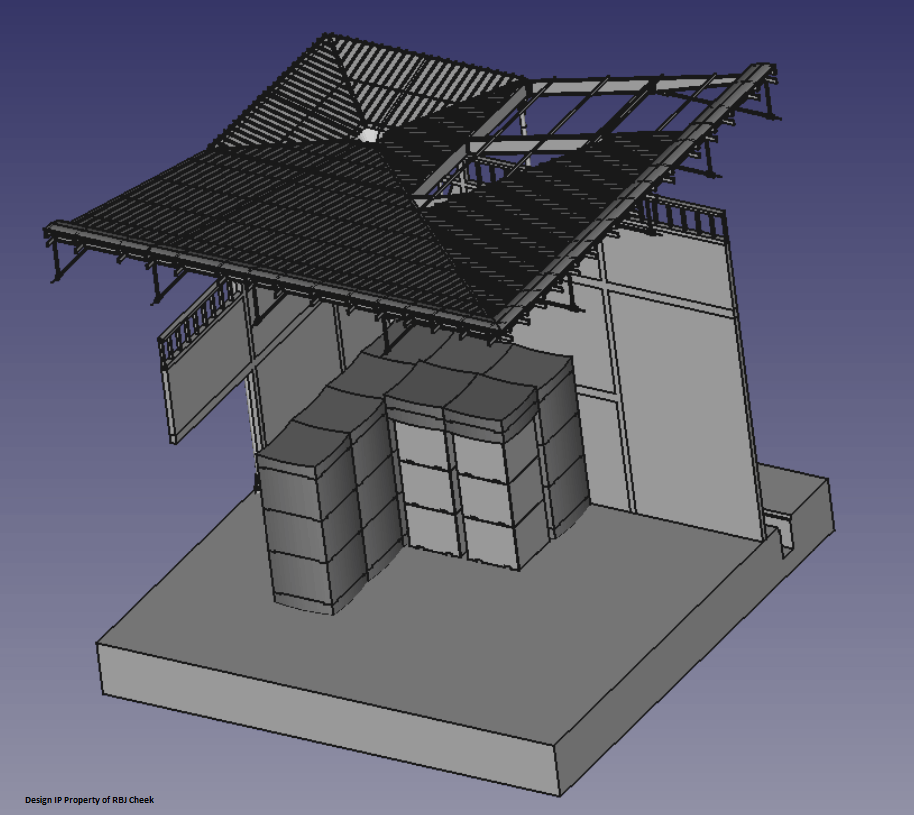

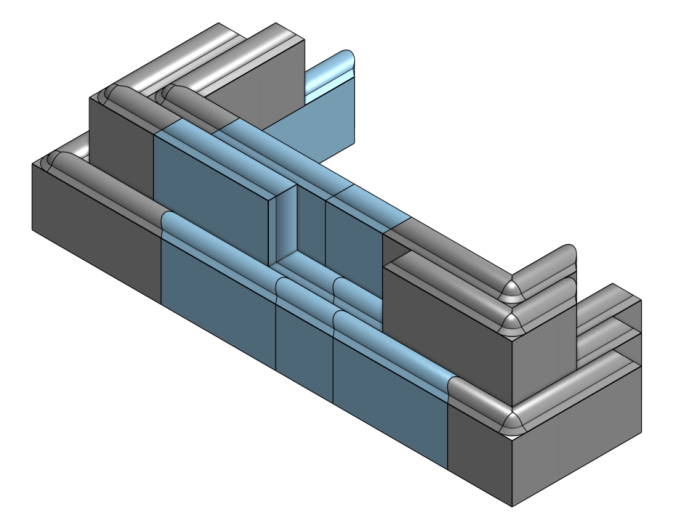

Utilising a heavy foundation with a standard portal frame building with OHT crane alongside concrete Universal Shielding Blocks (USB’s) that can be used to provide both horizontal and vertical shielding within a lightweight weather tight structure, Nuclear Facility Operators can create a flexible, fast deployed, interim storage facility. The shielding system utilises three shaped interlocking blocks and due to their registered design geometry they can offer appropriate shielding to containers of different overall dimensions unlike other more simple shielding blocks that are sized to fully shield only one container design.

Universal Shielding Block designs can be scaled to meet customer requirements & are registered designs with the UK Intellectual Property Office.

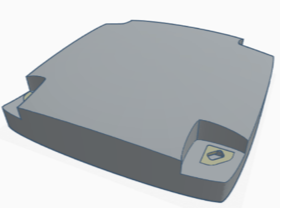

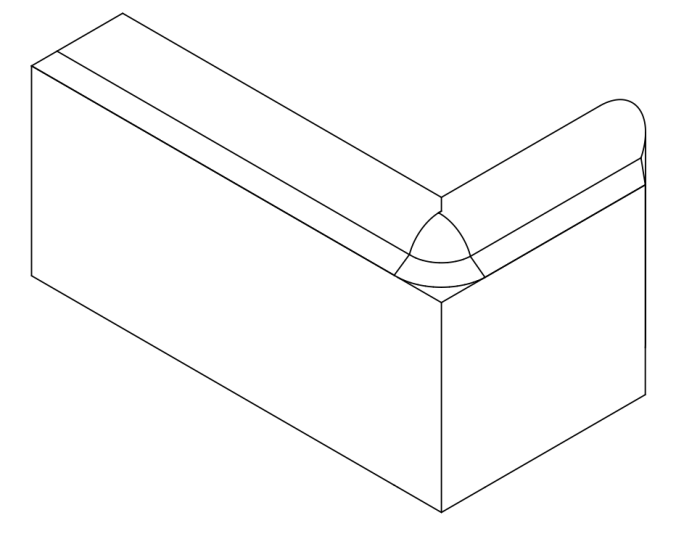

The Base Block is used as the foundation layer and sets the overall footprint of the shielded facility or area. Depending on ground level shine and the waste package to be used the Base Block can sit directly on a foundation slab or recessed in an outer groove in the foundation slab. The Base Block is also used in conjunction with the Capping Block to provide sky shine shielding when placed on top of a stack of waste packages.

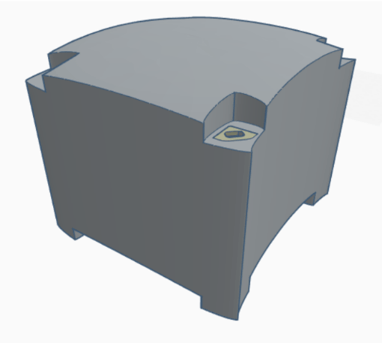

The Main Block, as its name suggests, is the block that will be utilised to create the stack or wall height required to provide the bulk shielding. The Main Block sits on the base block with additional Main Blocks stacked to reach the appropriate height. The stack is then topped off with a Capping Block. Depending on the customers & shielding requirements, this block can be manufactured with a cavity to reduce overall weight and cost.

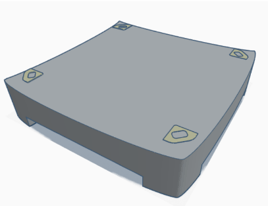

The Capping Block is the topping out block for a shielding block stack that can be used to provide the finished upper surface to the shielded facility. In addition, and in conjunction with the Base Block it provides appropriate level of sky shine shielding for a waste package stack but with the two blocks significantly lighter than the Main Block reducing the overall load applied to waste package stacks.

Shielding Brick designs are registered designs with the UK Intellectual Property Office.

Full Precast Lid or Partial Precast Lid replacing the wet cast lid with minimal changes to original UK 6m3 Reinforced Concrete Box (RCB) design. Developed to reduce the concrete batching and delivery plant (required to cast the wet lids) within a sites radiological control zone. The full precast lid design and the partial precast lid design are registered designs with the UK Intellectual Property Office.

The pre-curser of the 6m3 Robust Concrete Box (RCB) was the WAGR Box from the 1980’s. In many respects the 6m3 RCB and the WAGR Box remain similar in design including the provision of a “wet” cast lid.

The current 6m3 RCB does not come with a matched precast concrete lid, the lid being cast on the waste consigners site once the waste is within the box void and is immobilised. As such a significant amount of plant and equipment is required to be installed within controlled areas on a waste consigners site and the fact that the lid has to be fitted immediately after the waste is loaded and immobilised reduces the flexibility of the container for options such as reversibility which would allow early use of the container, decay storage and being able to take advantage of other waste processing options that may come along in the future.

To allow these restrictions to be overcome, to minimise additional plant on a waste consigners site and to introduce significant savings Raddecom Solutions has registered a concept design for a precast and partial precast concrete lid for the 6m3 Robust Concrete Box (RCB).

HTML Generator